Medical Plastic Injection Molding Manufacturers in USA

Anil Plastics and Enterprises is a leading Medical Injection Molding manufacturers in USA, suppliers and exporters in USA. We are experienced enough to offer top-quality plastic components and parts for the medical and health industry. Our concern is enabling the manufacture of healthcare technology through efficient manufacture of safe, reliable, and highly precise medical plastic injection molding components and parts that comply with international regulatory and quality standards.

Medical Injection Molding Suppliers in USA

With our use of state-of-the-art equipment, experienced cleanroom facility, and extensive medical device injection molding experience, we supply components used in diagnostics, surgical equipment, drug delivery systems, and lifesaving equipment. A medical device manufacturer, diagnostic solution provider, or consumable medical products supplier, we deliver customized-engineered medical injection molded parts that meet your technical specifications and patient safety. Anil Plastics and Enterprises does not simply mold plastic – we mold confidence into every product.

Types of Medical Injection Molding We Offer

A well-known Medical Injection Molding manufacturers in USA, we are providing the best quality of Medical Injection Molding such as:

- Diagnostic and Laboratory Parts

We produce highly precise components for diagnostic test kits, blood collection equipment, fluid handling trays, and reagent cartridge housings. The parts are extremely optically transparent, chemically resistant, and dimensionally stable – all achievable through medical-grade polymers, i.e., Polycarbonate and Polystyrene. Repeatability balance from our tools and aseptic production of the parts is ensured.

- Surgical and Device Housings

We manufacture complex handles and housings for surgical instruments, scanners, mobile diagnostic instruments, and monitors. Our medical plastic injection molding technologies are designed with regard to ergonomic use, bio-compatibility, and drop resistance. We deliver grip, control, and device security components in high-risk applications using overmolding and insert molding.

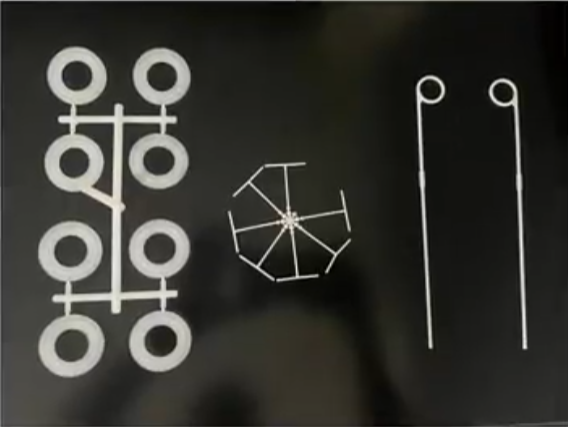

- Drug Delivery and Disposables

We produce disposable syringes, inhaler components, infusion connectors, cannula components, and needle caps with complete consistency and sterility. Our machines employ hot-runner molds and part ejection through robot to minimize cycle times and touchpoints. The products are FDA-approved, ISO-compliant, and produced in clean rooms to satisfy stringent medical device requirements.

- Custom Medical Plastic Parts

We work with OEMs and medical device manufacturers to design proprietary injection molded medical products to resolve specific challenges – from a custom surgical guide to a patient monitor accessory. Our DFM (Design for Manufacturing) support helps ensure part geometry is maximized for strength, functionality, and cost. We also offer prototyping and short-run production for early-stage medical technologies.

Key Features Our Medical Injection Molding

One of the leading Medical Injection Molding suppliers in USA, our all-types of Medical Injection Molding are included with new technological formulations such as:

- Class-Compliant Cleanroom Production: We carry out our plastic injection molding of medical equipment in ISO 13485-approved, controlled environments to avoid microbial and particulate contamination. Our equipment is sealed and computer-controlled to avoid the possibility of human contact when molding. This allows us to guarantee that all products are safe for use in medicine, even for sterile or patient-contact use.

- Use of Biocompatible and Certified Materials: We deal with only medically qualified thermoplastics such as Polypropylene, Polyethylene, TPU, PC, PEEK, and TPEs that are USP Class VI and ISO 10993 certified. These are non-toxic, chemically inert, and safe for use in contact with body fluids and drugs. Materials used by us are US as well as European medical device compliant.

- Precision Tooling and Tight Tolerances: We employ precision-grade stainless steel molds which are manufactured by CNC machining and Moldflow optimization for accuracy. It allows us to manufacture micron-level tolerances required in assembly-critical components, connectors, and fittings. Our tooling also supports high-speed as well as multi-cavity production with minimal maintenance.

Benefits of Our Medical Plastic Injection molding

These all types of new Medical Injection Molding are highly beneficial such as:

- Product Innovation through Speed and Customization: We enable rapid development cycles with in-house prototyping, tooling speed, and mold alteration capability. It provides early-stage medical technologies and start-ups competitive edge by driving time to market. Our flexibility is applied to create innovative part geometries for innovative drug delivery systems and miniaturized medical devices.

- Clinically Compliant and Patient-Safe Components: Our products are produced in clean facilities with medical-grade plastic to enhance patient safety as well as clinical dependability. We are certain that the kind of products will find their way into the body or used on therapy that saves lives. Therefore, we thoroughly test every batch of them for physical properties, dimensional accuracy, and body compatibility.

- Scalable and Repeatable Manufacturing: From prototype runs in small volumes to the manufacture of millions of units, our facility is expandable without sacrificing precision or defect levels. We maintain full production records and batch controls, meaning our parts are completely traceable and audit-ready. That's critical for FDA, CE, and ISO certification-compliant businesses.

Applications of Our Medical Injection molding Part

Being the best Medical Injection Molding exporters in USA, our all types of Medical Injection Molding are included with new feature and highly used in multiple applications such as:

- Hospital and Surgical Equipment: We supply parts for patient monitors, imaging, diagnostic probes and infusion pumps. Our molded housings and covers are rigid, sterilizable, and simple to assemble. They facilitate human interface and hardware integration in emergency and operating rooms.

- Diagnostic Labs and Pathology: We produce test tubes, fluid trays, cartridge holders, and microfluidic components that are used in diagnostic systems. They have to be of very high dimensional precision with no tolerance for contamination. Our molding parameters allow lab-ready components that enable accurate testing and analysis.

- Medical Consumables and Disposables: We supply our plastic solutions to disposable syringes, drip sets, respiratory masks, and catheter systems. They have to be hygienic and compliant to fulfill regulation requirements, but then they also have to be inexpensive enough to be disposed of once. We obtain great volume through multi-cavity molding without any cost in quality.

Why Choose Anil Plastics and Enterprises for Medical Injection Molding?

We are not just a producer — we're a valued partner of the healthcare value chain. Safety, efficiency, and innovation are given thought in every choice Anil Plastics and Enterprises undertakes.

- Certified and Controlled Production Environment: We maintain global standards of medicine and offer class-controlled molding conditions to ensure complete hygiene. Our cleanroom facility enables us to manufacture patient-contact as well as diagnostic plastic parts safely.

- Engineering Expertise for High-Risk Uses: We leverage decades of tool design, material science, and compliance knowledge to your medtech development programs. This removes risk, speeds up approvals, and provides uniformity in global supply chains.

- Total Traceability and Regulatory Support: Our documentation and batch control systems allow customers to trace every part back to its original production batch and raw material source. Audit support, FDA, ISO, and CE mark regulation documentation, and certifications are available with us.

Anil Plastics and Enterprises is a dominant Medical Injection Molding manufacturers in USA, suppliers and exporters in USA. At Anil Plastics and Enterprises, it is our passion to empower medical innovation with precision-plastic components that ensure safety, consistency, and performance. From producing life-saving devices to routine healthcare equipment, our high-quality medical injection molding solutions are crafted to meet your needs. Let's create scalable, dependable, and patient-safe components together — made in US, respected worldwide. Let's Shape the Future of Healthcare Together! Get in touch with us!