Enquire Now

Please Feel Free to Fill out the Form below with your requirements. We will get back to you within 1-2 business days.

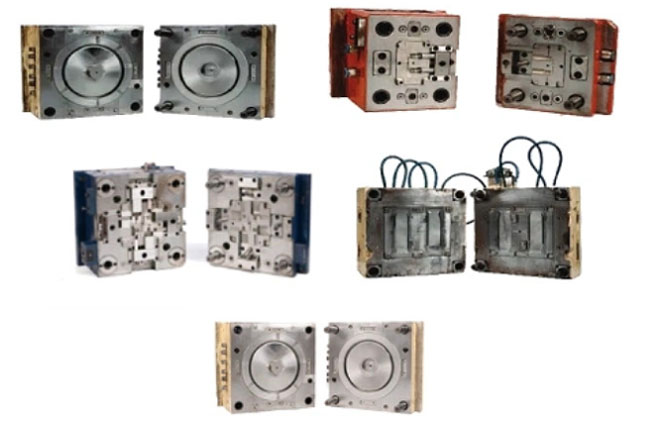

Our Products

Plastic Injection Molding | Plastic Mold Manufacturers in USA

Anil Plastics and Enterprises is a leading plastic mold manufacturers in USA, suppliers and exporters in USA, are offering the best quality of plastic molds. We have years of practical experience and a vision-based approach, and have demonstrated expertise in the business of delivering precision-plastic molds across diverse industries. We bridge the gap between the latest design tools, cutting-edge manufacturing techniques, and talented people to deliver world-class solutions.

Plastic Mold Suppliers in USA

We have developed year by year by improving our manufacturing process continuously and adjusting our services to meet the new needs of industries like automotive, electrical, electronics, packaging, and medical. Our plastic molds are technologically advanced, along with being adapted to clients' specifications for long-term operations, smooth manufacturing, and consistent quality. We provide various plastic injection-molded parts, automobile plastic parts, rubber parts, and electronic component molds for industrial and commercial applications.

Types of our Plastic mold

A well-known Plastic mold manufacturers in USA, we are providing the best quality of Plastic molds such as:

- Compression molds: We provide compression molds to mainly help rubber components and thermoset plastic components used in cars and electrical products. Our molds are made up of precision-fit cavities as well as highly sophisticated heaters that provide faster curing speed without degrading quality. Our recently acquired servo-controlled compression presses assist in maintaining strict process control and reducing manufacturing time.

- Blow molds: Our blow molds find ideal usage in the manufacturing of hollow articles like bottles, containers, and plastic tanks. We use advanced design software for simulation of air flow and material expansion to ensure even thickness and stability of the final product. With computer temperature control and automation of preform handling, our molds now give shorter cycles and lesser material wastage.

- Insert molds: Insert molds are made for components with embedded items such as metal fasteners or threaded bushings. They are discovered to have extensive application in plastic injection-molded electronic components, switchgear components, and hybrid components. We utilise robot insertion systems in our daily operations that enable gapless insert placement with micron accuracy to optimise part reliability.

- Injection molds: We are experienced plastic injection mold manufacturers of precision-grade plastic injection molds that can be used to mass-produce intricate plastic parts. Our molds are widely utilised for the manufacture of plastic components of automotive, consumer electronics, medical equipment, and home appliances. As a result of new tool steel as well as optimised flow channel designs, our injection molds now have reduced cycles and extended life usage.

Key Features of Our Plastic mold

One of the leading Plastic mold suppliers in USA, our all-types of Plastic molds are included with new technological formulations such as:

- Precision Engineering: We employ the latest CAD and CAM technology together with CNC and EDM machines to obtain extremely accurate tooling. All cores and all cavities are machined to micron tolerance for batch-to-batch consistency. Our dimensional accuracy ensures parts that go together perfectly in final assembly without post-processing.

- Custom Plastic Injection Solutions: Each mold we produce is customised to our own client's specifications, such as part geometry, material type, and manufacturing environment. If you need clear plastic molds or impact parts molds, we build each mold to your own specification. Our design engineers partner with customers from early concept through to final test.

- Surface Finish and Durability: Our molds are polished and surface hardened for the purpose of providing finer finishes, which bring beauty to products. We also employ anti-corrosion coating and nitriding treatments for increasing mold life in massive-volume applications. The outcome is a longer-lasting mold that produces higher and needs less repair.

Advantages of using Our Plastic mold

These all types of new plastic molds are highly beneficial such as:

- Consistent Product Quality: Our plastic molds deliver the same result in tens of thousands of production cycles. This is a result of our accurate tooling, mold-level temperature control, and optimised gating systems. Your finished parts will always be to dimension and appearance tolerance without exception.

- Decreased Production Costs: With mold design and automation technology, our customers have reduced defects and cycle time. This saves them great amounts of material wastage and optimises overall profitability. Our molds are simpler to maintain, thus saving on operating costs.

- Scalable Production Capability: We supply molds for small batch and large-scale automated production. Our design is modular in nature, allowing it to be easily changed and reconfigured without requiring full replacement. Such flexibility allows customers to quickly adapt to the demands of the marketplace.

- Long-Lasting Technical Support: We offer meticulous support from prototyping to post-delivery support. Our technical support is also accessible in-house, service, tooling optimisation, and preventive maintenance instructions. We assist you in maintaining your operations smoothly and economically.

Applications of our Plastic mold

Being the best Plastic mold exporters in USA, our all types of Plastic molds are included with new feature and highly used in multiple applications such as:

- Automotive Industry: We manufacture molds for components such as bumpers, dashboards, door trims, and under-hood components. Our molds are made to support materials that are heat-resistant, wear-resistant, and impact-resistant. Our molds provide assistance to next-generation vehicle design with lightweight plastics developments and part consolidation advancements.

- Consumer Electronics: Our molds create plastic connectors, enclosures, and complex housings found in telephones, computers, and other electronic equipment. We mold with high-flow resins and precision vents for tight tolerances and perfect appearance. The molds are ESD-safe and electronic-grade performance level compliant.

- Medical Devices and Healthcare Products: We manufacture syringe molds, blood tube molds, inhaler molds, and other medical-grade plastic components. We make these molds in clean rooms using sterilisation and biocompatibility-cleared materials. We do sensitive applications with cleanroom manufacturing processes.

- Packaging and Consumer Goods: We supply cosmetic container molds, food package containers, closures, and kitchenware. Our high-speed multi-cavity mold, optimised thin-wall molding and stack molding technology, allows for fast cycle times and minimum plastic usage per unit.

Why Choose us?

- Manufacturing Expertise: Decades of experience in plastic mold design and manufacturing, with a focus on technical excellence and reliability.

- Comprehensive Services: End-to-end manufacturing capabilities, from design to validation, ensuring faster lead times and cost efficiency.

- Customised Solutions: Tailored molds optimised for performance, speed, and minimal material waste, meeting specific product and production needs.

Anil Plastics and Enterprises is a leading plastic molds manufacturers in USA, suppliers and exporters in USA, are offering the high quality of plastic molds. Our rich experience in mold making, material science, and manufacturing optimization enables our clients to be one step ahead. From a failed bespoke plastic injection mold to bulk plastic injections mold & dies, we have solutions that keep pace with your business. For more information, contact us today!